| Machine | Quantity | Best Price |

YQ-L800 Automatic Carton Erecting Machine  |

1 SET | FOB NINGBO 14250 USD |

Belt 25mm  |

8 pcs x USD 15 | 120 USD |

| SASO certificate | 100 USD | |

| TOTAL : 14470 USD | ||

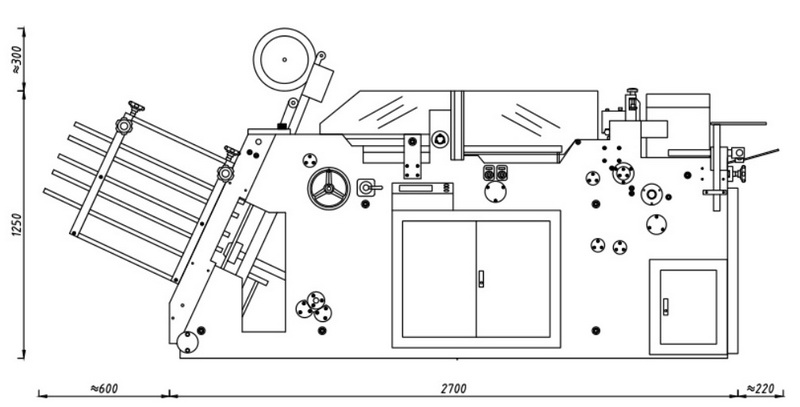

| Type | YHZH carton box erecting forming machine |

| Suitable material: | 200-600gsm white card board, PE coated paper, Kraft paper, corrugated paper |

| Production speed: | 50-120pcs/min |

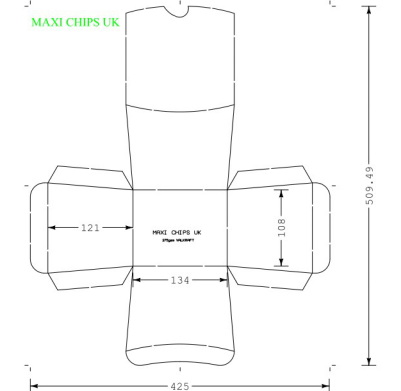

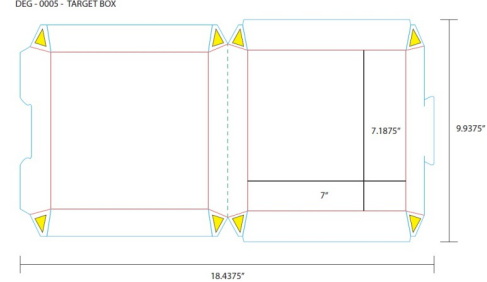

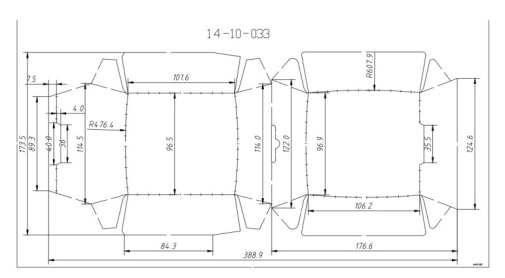

| Blank paper size: | Length 100-450mm, Width 100-580mm, Height 15-200mm, Angle 4-50° |

| Blank paper weight: | Max. 3mm for corrugated paper |

| Total power: | 4.5KW |

| Total weight: | 2300KGS |

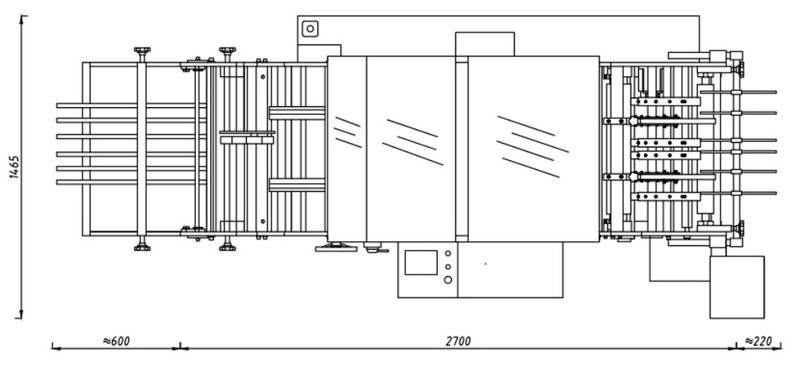

| Overall dimension: | 3520*1465*1550mm |

| Packing dimension: | 3560x1510x1690mm |

| Power source: | 380V, 50HZ |

| MAIN ELECTRICAL PARTS LIST:(BRAND) | |

| 1) Frequency converter |  Simens, German Simens, German |

| 2) Programmable controller: |  Simens, German Simens, German |

| 3) PLC power: | Simens, German |

| 4) Touch panel : | Simens, German |

| 5) Photo electronic switch: | Autonics, Korea |

| 6) A.C contactor : | Simens, German |

| 7) Button: | Simens, German |

| 8) Reply: | Simens, German |

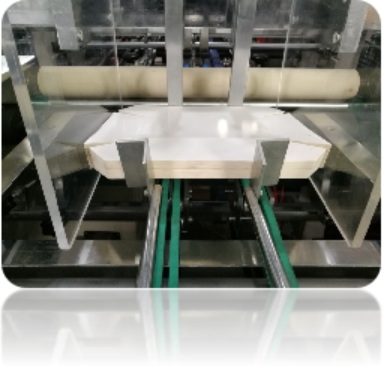

Machine brief details:

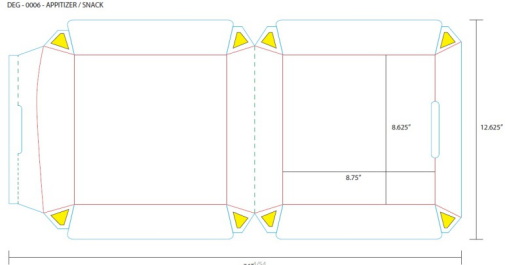

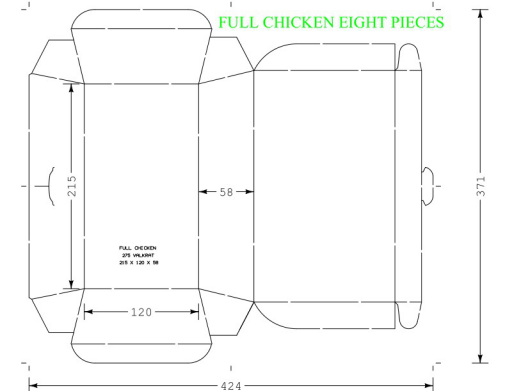

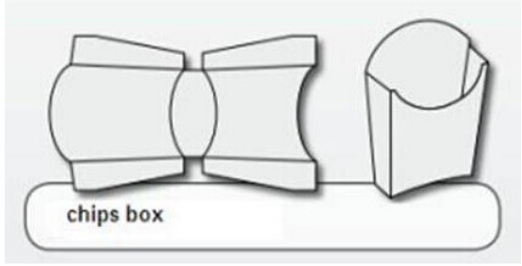

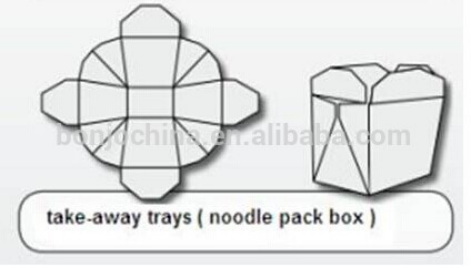

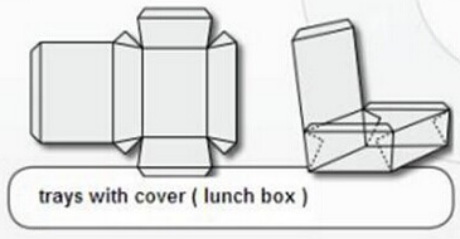

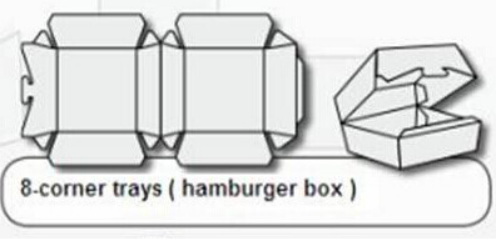

1). It is an ideal equipment to produce paper box such like hamburger box, chips box, fried chicken box, kids meal box, fast food box, fast noodles box etc.

2). With firm structure, high quality, low noise and high efficiency.

3). It has paper feeding unit, adjusted unit, glue unit, forming unit, finished products collecting unit and also counting unit.

Main differences and advantages:

1). With very experienced engineers and designer, we never stop, keep improving and perfecting on machines. We can put plasma device, hot melt glue device on the machine as customer required.

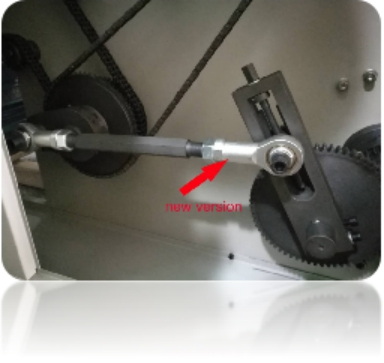

We were the first factory in China choosing servo motor for feeding paper system instead of traditional cam system, it have less noise and easier to adjust in order to make different size and shape boxes. In the year of 2014, we have applied to Patents and the number as below.

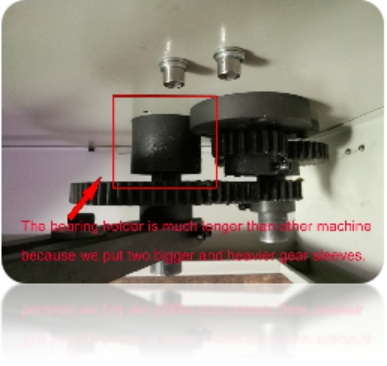

3). We improved and use bigger and heavier gear sleeve instead of usual small gear sleeves, help in machine running more stable.

4). All the gears have been second processed by gear grinding machine, in order to make it smooth, then go quenching treatment. For those parts we pay extra processing money because we want it to be perfect quality.

5). The Old style of glue system, when the glue on paper box corner, just gluing on point, and the box gluing is not uniform when formed, but now, we improved the glue system and adding one set of glue wheel under the glue container, when gluing on paper corner, the up and down wheel kiss together and make the glue on paper more uniform, and it make the glue more uniform.

6). Auto counting and collecting system.

7). PLC and Touch screen.

Available box can be made by our box forming machine

FREE SPARE PARTS LIST

| No. | Spare part |

Quantity |

Picture |

| 1. | BOX | 1 Set |

|

| 2. | Inner hexagonal spanner | 1 Set |

|

| 3 | Screwdriver(+ -) | 2 pcs |

|

| 4 | Open-end wrench | 1 pcs |

|

| 5 | Oil Gun | 1 pcs |

|

| 6 | Needle nose pliers | 1 pcs |

|

| 7 | Hammer | 1 pcs |

|

| 8 | White cotton tape | 1 pcs |

|

| 9 | Cushion | 4 pcs |

|

| 10 | Air connection | 4 pcs |

|

| 13 | Inhale rubber | 2 pcs |

|

Other parts should be determined according to your product mould

Remarks:

a. Price term: FOB Ningbo Port, China

b. Mold cost: 1 free, extra molds need to pay $80.

c. Payment terms: T/T, 30% deposit first, 70% balance before shipment.

d. Loading time: 15 working days at sight of deposit and mold drawing confirmation.

e. Package: wooden packing applies to export.

f. After-sale service: Spare parts enjoy one year guarantee after machine arrival. Technician

will be sent to install and teach, buyer bears all costs (e.g., visa, round ways tickets,

accommodation, salary of 80 dollars per day.) Our technician has American visa so if your

country accept this, then no need to pay for visa cost.